SMOC X-RAY DETECTOR

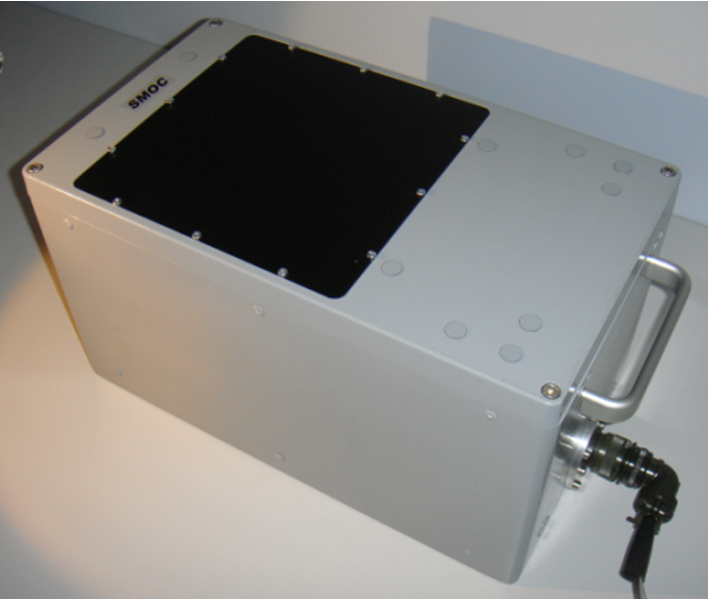

Digital SMOC (Scintillator, Mirror, Optics, Camera) X-Ray detector developed by scientists of the “Świerk” National Centre for Nuclear Research. The device was designed on the basis of a scintillator, high quality silver mirrors, optical system and CCD sensor. The SMOC X-Ray detectors belong to DDR (Direct Digital Radiography) family, i.e. devices used for direct imaging, their construction was optimized for the highest resistance in long-lasting operation with high levels of energy (of up to 15 MeV) and high radiation doses.

The advantages of digital radiography (DR) make it ever more popular in non-destructive testing (NDT), where it competes with traditional films and the indirect Computer Radiography (CR).

RESOLUTION AND PRECISION OF SMOC X-RAY DEVICES

The SMOC family detectors achieve good results in test accuracy. In case of imaging large, dense objects with use of an accelerator the accuracy of detected defects or differences in structure is ca. 0.5% of the element thickness. Thus when imaging a 100 mm thick steel element it is possible to capture differences in its structure (e.g. void, crack, inclusion, etc.) with a width and depth of just 0.5 mm.

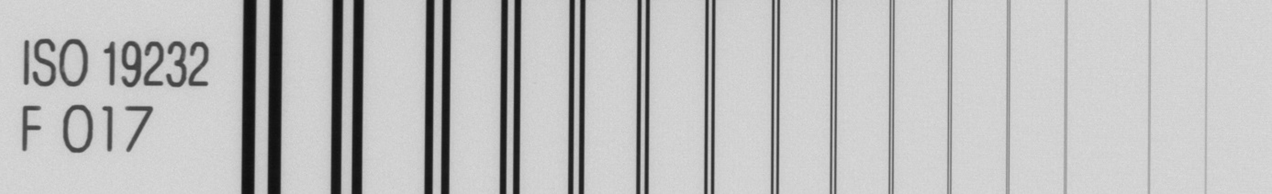

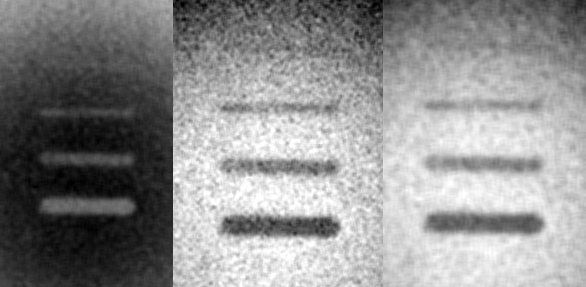

The SMOC_HE (High Energy) and SMOC_STD (Standard) detectors achieve 7D (0.2mm) level, when tested with use of two-wire method, according to the ISO 19232 standard. This method consists of imaging two wires of identical thickness that are spaced apart by the thickness of each of them. Achievement of a respective level of detector accuracy means that both wires and the space between them are visible in the image captured. Even greater accuracy – of ca. 0.08mm = 80um – can be achieved with use of the SMOC_HR (High Resolution) device.

Digital x-ray image (positive, negative, smoothening filter) of a 250 mm thick steel block with 4 grooves in it: of a width and depth of: 5 mm/3.75mm/2.5mm/1.25mm, respectively. The three first (counting from the bottom) are well visible, the fourth outlined. The image was captured with use of a linear accelerator and the SMOC_HE_40x40 detector.

X-ray image of a weld, 10mm thick steel sheets. Captured with use of the SMOC_HE_40x40 detector, beam energy 220kV . The image meets the Class B requirements. Above the image of weld, below its magnification, a fragment of the same X-ray image with digitally enhanced parameters to make the wires visible.

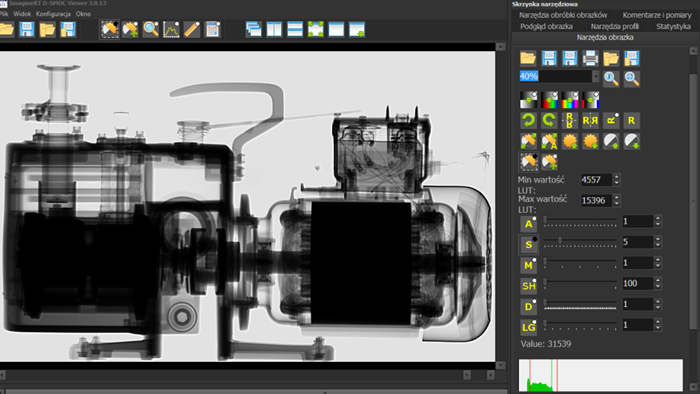

SMOC DETECTORS SOFTWARE

The SMOC X-Ray detectors are equipped with the dedicated, stable and tested ImagineRT D-SMOC software suite. Its current version is the result of several years of development. The friendly and intuitive interface will allow even the novice user to perform advanced X-ray image analysis. The software was developed for its use in non-destructive testing and for scientific experiments.

Functions of the ImagineRT D-SMOC software suite:

- Standard display of high-depth images

- Processing and saving x-ray images (with all changes and comments)

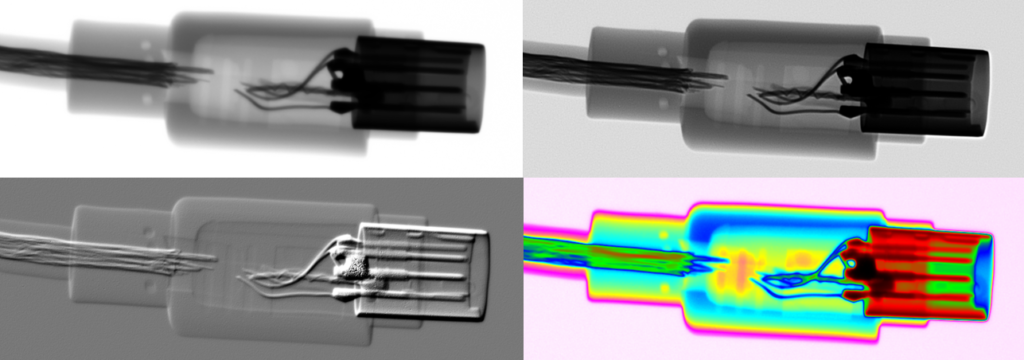

- Digital filters for image enhancement or detail visualization (smoothening, sharpening, differential, false colour, positive/negative, and other)

- Tools for geometric measurements (length, width, angle)

- The possibility to zoom on details, adjust brightness and contrast, rotate the object, add comments, etc.

- Language versions: Polish, English or Italian. Any other language can version can be added in the future.

- Reads most of the known graphic formats used in X-ray imaging (including but not limited to HIF,DICOM/DICONDE, 16-bit TIFF),

- The ability to save images (also with all changes recorded) in the following formats: CFT3, CFT4, TIFF, DICOM/DICONDE, PFM, PGM, as well as the typical graphic formats: JPEG & BMP,

- Can also work (apart from SMOC family detectors) with selected models of flat panel detectors.

- Integration of detectors with radiation sources

The ImagineRT D-SMOC software was created as an open-architecture software, thus allowing the addition of other, non-standard functions.

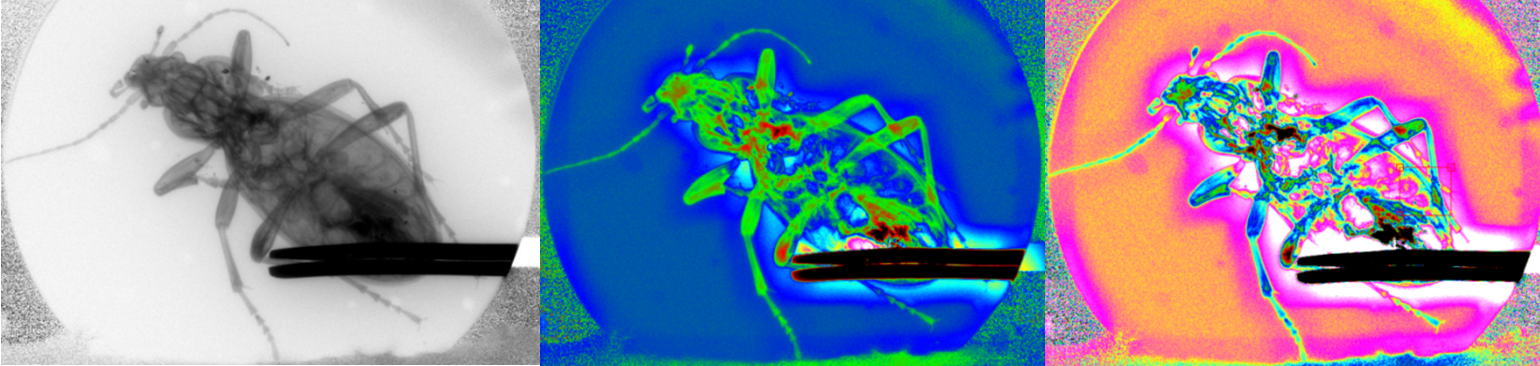

A plug with defects: standard digital X-ray image (without filters), sharpening filter (contours are better visible), differentiating filter (3D appearance, better structure imaging of e.g. brazing), false colour (better differentiation of density and type of material used).

APPLICATION OF SMOC DETECTORS

The SMOC detectors are best used in stationary applications in factories, foundries, NDT laboratories and research institutes.

THE MANUFACTURER

The digital SMOC X-ray detector was developed by specialists of the “Świerk” National Centre for Nuclear Research. The device is currently manufactured under license by the ImagineRT sp. z o.o. Company. The detectors are manufactured on order, enabling the customer to adjust the parameters (e.g. the area of active surface, the scintillator, etc., additional software functions) to its particular needs and requirements.

| Technical Specification | |

|---|---|

| Energy range | SMOC_STD from 40 keV to 500 keV SMOC_HE from 100 keV to 15 MeV |

| Detector sensitive area | from 200 x 200 mm to 1000 x 1000 mm and more (individual request possible) |

| Image sensor | CMOS/CCD |

| Grey scale | 16-bit (65536 shades of gray) |

| Image dynamics | 16-bit (65536 shades of gray) |

| Size of the pixel | ≤ 150µm for the imaging field 400 x 400 mm |

| Number of pixels | min. 36 Mpx |

| Time to prepare for work | < 1min. |

| single frame acquisition time | from 0.01 to 300sec. |

| Communication protocol | Gigabit Ethernet Wi-Fi (optionally) |

| Power supply | 230V battery (optionally) |

| Cable length detector – PC | 40 m (standard) possibility of extension / shortening (optionally) |

THE ADVANTAGE OF THE DEVICE OVER OTHER METODS

In comparison to films

- image obtained immediately

- image in digital form

- possibility of improving image quality with digital methods

- no need to use chemical solvents, which in the long run translates into lower costs

- significant saving of time and workload

- lower archiving costs

- the ability to efficiently search and reproduce images with the information assigned to them

- no aging effect

- fast access to test results from many places by computer network

In comparison to CR detectors

- image obtained immediately without the necessity of indirect reading

- low sensitivity to mechanical damage (scratches, etc.)

- no “ghost" effect, i.e. remnants of the previous image

- no “fadding" phenomenon, i.e. disappearance of the recorded image between

- the acquisition of the CR plate and its reading by the scanner

In comparison to DR detectors based on amorphous silicon matrices

- greater resistance to radiation, which gives a longer life

- no effect of damaged pixels

- size of the detector adapted to the customer’s needs

TYPES OF THE SMOC DETECTORS:

SMOC_HE (High Energy)

For high energy ranges, with sources like linear accelerator or betatron we developed the SMOC_HE (High Energy) version

of the detector. The thicker scintillator and integrated shielding protecting the sensitive elements allow its long lasting and efficient operation in energy range of 1 – 15 MeV. The active area of the detector may be adjusted to the needs of the customer, and its dimensions may even exceed 1 m x 1 m. Till present date we manufactured the following versions of the SMOC_HE device: SMOC_HE_40x40 (with an active area of 40×40 cm); SMOC_HE_40x60; SMOC_HE_50x60; and SMOC_HE_80x100.

SMOC_STD (Standard) for keV range energies

The SMOC_STD – Standard detector – with active area of 20cm x 20cm is adjusted to working in energy range corresponding to X-ray tubes and radionuclides such as Ir-192 or Se-72. We can build detectors with other sizes of active area, adjusted to needs of the customer.

SMOC_HR (High Resolution)

The SMOC_HR – High Resolution detector is designed to work with radiation energies of up to 300 keV. It is characterized by its exceptionally high resolution. In case of double-wire template its resolution is 11D (0.08mm). However the imaging time is several times the time required to capture the image with use of the remaining SMOC detector types. The active area of the SMOC_HE detector is 10x13cm or multiplication of this size, which can be achieved (without sacrificing the resolution) by increasing the number of cameras used.

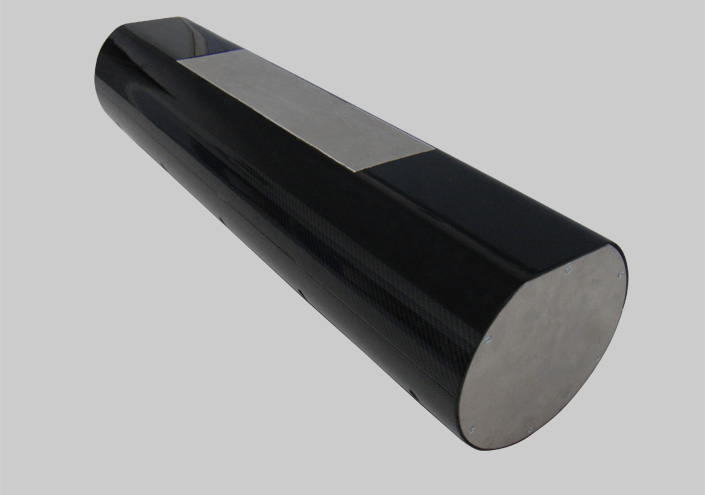

Special applications

The ImagineRT company introduced dynamic imaging capabilities in its products. The recording speed is 25 frames/s Full-HD resolution, allowing for high quality imaging where the rotation or sliding of the tested object with “liveview” preview is required. The ImagineRT company also offers dedicated non-standard solutions, for example the SMOC_L – Long detector for testing welded longitudinal joints in pipes (active area 300mm x 80mm) in the following configuration: source of radiation outside the pipe, the detector inside it. Its small dimensions allow it to be used to test longitudinal welds of pipes with diameters of 170mm and more.